Standard Mechanical Seals

Standard Mechanical Seals: The Definitive Guide to Reliable Shaft Sealing Solutions

In the world of industrial machinery and fluid handling, preventing leaks at rotating shafts is paramount for efficiency, safety, and environmental compliance. The Standard mechanical seal stands as the fundamental and most widely deployed solution for this critical task. Unlike rudimentary packing, a mechanical seal is a precision-engineered component that creates a much more effective and durable barrier. This comprehensive guide delves into the design, functionality, key parameters, and selection criteria for standard mechanical seals, providing the technical insight necessary for optimal application and performance.

1. Material Compatibility

The construction materials must be compatible with the process fluid, temperature, and any cleaning agents. Here is a standard material selection matrix:

| Component | Common Material Options | Typical Properties & Applications |

|---|---|---|

| Primary Face (Hard) | Silicon Carbide (SiC), Tungsten Carbide (WC), Alumina Ceramic (Al2O3) | Extreme hardness, excellent chemical resistance, good thermal conductivity. SiC is superior for abrasive slurries. |

| Primary Face (Soft) | Carbon Graphite (Resin-impregnated), PTFE | Self-lubricating, conforms to the hard face. Various impregnations (e.g., resin, antimony, bronze) enhance chemical and wear resistance. |

| Secondary Seals (Elastomers) | NBR (Nitrile), EPDM, FKM (Viton®), FFKM (Kalrez®) | NBR for oils/water; EPDM for steam/polar fluids; FKM for fuels/aromatics; FFKM for aggressive chemicals and high temps. |

| Metal Parts | Stainless Steel (304, 316), Hastelloy C, Duplex Steel | 316SS is standard for corrosion resistance. Exotic alloys are used for highly corrosive environments (e.g., chlorides, acids). |

| Springs | Stainless Steel 316, Hastelloy C, Inconel | Must resist corrosion from the process fluid to maintain loading force. |

2. Operating Limits

Every seal is designed for a specific window of operation. Exceeding these limits leads to premature failure.

- Pressure (PSI/Bar): Standard cartridge seals typically handle up to 250 PSI (17 bar). Balanced seal designs are required for higher pressures.

- Temperature (°F/°C): Standard elastomers (NBR, EPDM, FKM) range from -40°F to 400°F (-40°C to 204°C). High-temperature designs use FFKM, metal bellows, and specialized face materials.

- Shaft Speed (RPM / Surface Speed ft/min): Limited by the PV (Pressure x Velocity) value of the face materials. Standard seals are suitable for speeds up to 3600 RPM on typical pump shafts.

- Shaft Size: Available for a vast range of shaft diameters, commonly from 0.5 inches (12mm) to over 6 inches (150mm).

Standard Mechanical Seals - Frequently Asked Questions (FAQ)

Q: What is the main advantage of a standard mechanical seal over traditional gland packing?

A: Mechanical seals offer significantly lower leakage rates, often reducing leakage to a negligible vapor or a few drops per day compared to the constant dripping or spraying of packing. They require far less maintenance (no periodic adjustment/tightening), reduce shaft or sleeve wear, and lower power consumption due to drastically reduced friction on the shaft.

Q: How do I know if my application needs a standard mechanical seal or a more advanced "balanced" seal design?

A: The key deciding factor is seal chamber pressure. A standard (unbalanced) mechanical seal is generally suitable for pressures below 200-250 PSI in water-like fluids. If your pump discharge pressure (or more accurately, the pressure at the seal chamber) exceeds this range, or if you are sealing a volatile fluid with a low vapor pressure, a balanced seal design is required. Balanced seals offset hydraulic pressure acting on the seal faces, preventing face separation and excessive heat generation at higher pressures.

Q: What are the most common causes of premature mechanical seal failure?

A: The vast majority of failures are due to improper operating conditions or installation, not material defects. Common causes include: 1) Dry Running: Operating the pump without fluid, even for seconds, causes instant heat cracking of the faces. 2) Incorrect Installation: Improper setting of the seal face compression, damaged O-rings, or misalignment. 3) Process Upsets: Cavitation, sudden temperature spikes, or solid particles entering the seal chamber. 4) Chemical Attack: Selecting elastomer or face materials incompatible with the fluid or cleaning agents.

- View as

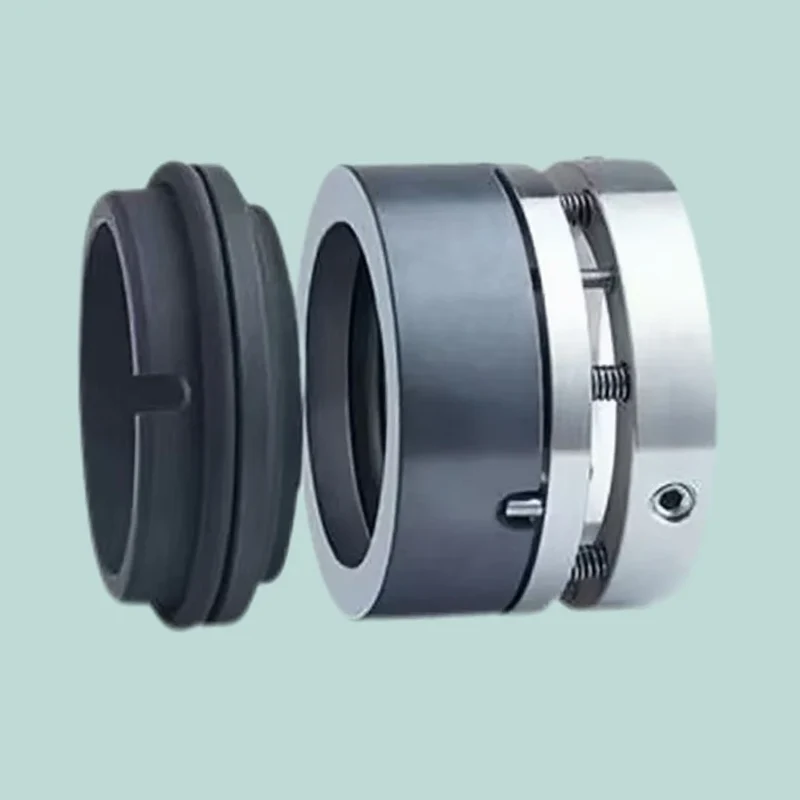

O Ring Mechanical Shaft Seal 8-1T Multi Spring Mechanical Seal

You can rest assured to buy O Ring Mechanical Shaft Seal 8-1T Multi Spring Mechanical Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

PTFE 9T John Crane Mechanical Seal Leak Proof Mechanical Seal

You can rest assured to buy John Crane Type 9T Replacement Multi-Spring PTFE Wedge Mechanical Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

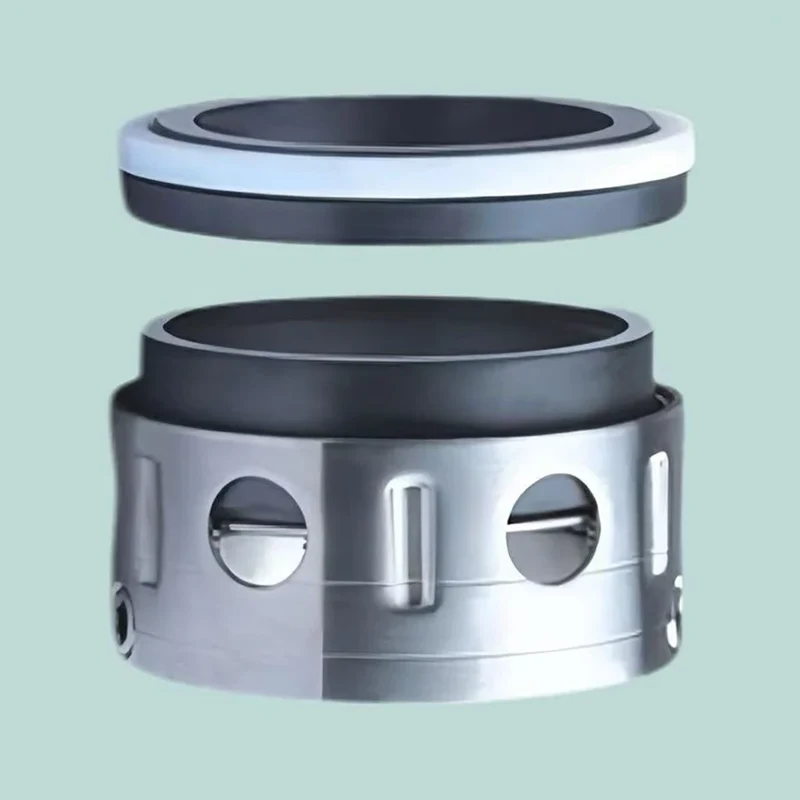

Double Face Mechanical Seal XEDXM Suit For Pump 35/70/80/120mm

You can rest assured to buy Double Face Mechanical Seal XEDXM suit for pump 35/70/80/120mm Mechanical Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

58U General Purpose DIN, Multi-spring, O-ring Pusher Seal

You can rest assured to buy 58U General Purpose DIN, Multi-spring, O-ring Pusher Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

RO Multiple Spring and O-ring Pusher Mechanical Seals Replace Flowserve RO Mechanical Seals

You can rest assured to buy RO multiple spring and O-ring pusher mechanical seals replace Flowserve RO mechanical seals Mechanical Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

8T Multi-spring Mechanical Seal,Replacement To John Crane 8-1T

You can rest assured to buy 8T Multi-spring Mechanical Seal,Replacement To John Crane 8-1T Mechanical Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.