Mechanical Seals Spare Parts

Key Technical Specifications and Parameters of Mechanical Seals and Their Spare Parts

For engineers and maintenance professionals, selecting the correct Mechanical Seals Spare Parts is a precise science. It requires a deep understanding of operational parameters to ensure compatibility, longevity, and optimal seal performance. Below are the critical technical specifications that must be evaluated.

Primary Material Specifications

The choice of materials directly impacts the seal's resistance to the process media, temperature, and pressure. Key material groups include:

-

Face Materials:

- Carbon Graphite: Excellent self-lubricating properties, good chemical resistance. Common grades include EK-2800, 2190.

- Silicon Carbide (SiC): Superior hardness, excellent thermal conductivity, and superb chemical resistance. Available in sintered alpha SiC and reaction-bonded SiC.

- Tungsten Carbide (WC): Extremely hard and wear-resistant, typically used in slurry applications. Often coated with chrome oxide (WC/Cr).

- Alumina Ceramic (Al2O3): High hardness and good abrasion resistance, cost-effective for many standard services.

-

Elastomer Secondary Seals (O-Rings, Gaskets):

- Nitrile (NBR/Buna-N): Good for oils, water, and petroleum-based fluids up to ~100°C.

- Fluoroelastomer (FKM/Viton®): Excellent chemical and high-temperature resistance (up to 200°C+).

- Ethylene Propylene Diene Monomer (EPDM): Excellent for steam, hot water, and polar chemicals. Poor for hydrocarbons.

- Perfluoroelastomer (FFKM/Kalrez®, Chemraz®): Near universal chemical resistance for severe services.

-

Metal Components (Housings, Springs):

- Stainless Steel 316: Standard for good corrosion resistance.

- Alloy C276 (Hastelloy): For highly corrosive environments (e.g., chlorides, sulfuric acid).

- Duplex Stainless Steels: For applications requiring high strength and chloride stress corrosion cracking resistance.

Comprehensive FAQ on Mechanical Seals Spare Parts

General Selection & Identification

How do I correctly identify the mechanical seals spare parts I need?

Always start with the original equipment manufacturer (OEM) part number from the seal's metal tag or the equipment manual. If unavailable, provide precise measurements: shaft diameter, bore diameter, seal face widths, overall length, and spring configuration. Clear photographs from multiple angles of the old seal are invaluable. The process fluid, temperature, and pressure are also mandatory for verification.

Can I mix seal faces from different manufacturers?

It is strongly discouraged. Seal faces are lapped as matched pairs to achieve the required flatness and surface finish. Mismatching faces from different batches or manufacturers can lead to leaks, excessive heat generation, and premature failure due to poor mating characteristics.

What is the single most important factor when selecting spare seal parts?

Material compatibility with the process fluid is paramount. An incorrect elastomer or face material will degrade rapidly, causing immediate and catastrophic seal failure. Always consult chemical resistance charts and, when in doubt, opt for a more chemically inert material like Silicon Carbide and FFKM.

Materials & Performance

What is the difference between Reaction-Bonded and Sintered Silicon Carbide?

Reaction-Bonded SiC (SiSiC) has free silicon in its matrix, offering excellent corrosion resistance but slightly lower temperature capability (~1400°C) and can be attacked by strong caustics and hydrofluoric acid. Sintered Alpha SiC (SSiC) is purer, with no free silicon, providing superior chemical resistance across a broader pH range and higher temperature limits (~1650°C), making it the premium choice for severe services.

When should I choose a metal bellows seal over a spring-loaded design?

Metal bellows seals eliminate the need for dynamic elastomers (O-rings that slide on the shaft), making them ideal for high-temperature applications beyond elastomer limits, or for fluids that crystallize or polymerize, which can clog spring assemblies. They are often preferred in light hydrocarbon services, hot water, and many refinery applications.

My O-rings are swelling and degrading quickly. What does this indicate?

This is a clear sign of chemical incompatibility. The elastomer is absorbing or reacting with the process fluid. You must upgrade to an elastomer with better resistance, such as moving from NBR to FKM, or FKM to FFKM for highly aggressive chemicals. Review the fluid's exact composition and temperature.

Technical & Compliance

What does "balanced" vs. "unbalanced" seal design mean?

This refers to the hydraulic forces acting on the seal faces. In an unbalanced seal, the full process pressure acts to close the faces, which can generate excessive heat and wear at higher pressures. A balanced seal incorporates a step in the sleeve or seal head to reduce the hydraulic closing force (hydraulic balance ratio <1). This allows operation at much higher pressures, reduces heat generation, and improves life. Balanced designs are standard for pressures above 200-300 psi.

What is API 682, and why is it important for spare parts?

API 682 is a rigorous standard published by the American Petroleum Institute for shaft sealing systems in centrifugal and rotary pumps in the hydrocarbon and chemical industries. It dictates requirements for seal design, testing, materials, and piping plans. Using API 682-compliant spare parts ensures proven reliability, safety, and interchangeability for critical service equipment, reducing risk and unplanned downtime.

How do I interpret the seal face lapping specification, e.g., "3 helium light bands flat"?

This specifies the flatness of the sealing faces. One helium light band represents a deviation of 0.0000116 inches (0.294 micrometers). "3 light bands flat" means the faces are flat within 0.0000348 inches. Flatter faces (1-2 light bands) provide better sealing, especially for low-pressure or volatile fluids, while 3 light bands is a common, robust standard for general service.

- View as

Stationary Ring Mechanical Seals T20 SSIC And Rbsic Stationary Seal

You can rest assured to buy Stationary Ring Mechanical Seals T20 SSIC And Rbsic Stationary Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

Silicon Carbide Ring Burgmann Mechanical Seal Spare Parts G60 Stationary Seat For Pump

You can rest assured to buy Silicon Carbide Ring Burgmann Mechanical Seal Spare Parts G60 Stationary Seat For Pump from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

Silicon Carbide Ring Burgmann Mechanical Seal Spare Parts G6 G606 Stationary Seat

You can rest assured to buy Silicon Carbide Ring Burgmann Mechanical Seal Spare Parts G6 G606 Stationary Seat from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

Mechanical Seal Spare Parts BP Stationary Seat Silicon Sealing Ring SIC Stationary Seal

You can rest assured to buy Mechanical Seal Spare Parts BP Stationary Seat Silicon Sealing Ring SIC Stationary Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

502 BO Mechanical Seal Statioanry Silicon Carbide Seal Ring BO Seat

You can rest assured to buy 502 BO Mechanical Seal Statioanry Silicon Carbide Seal Ring BO Seat from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

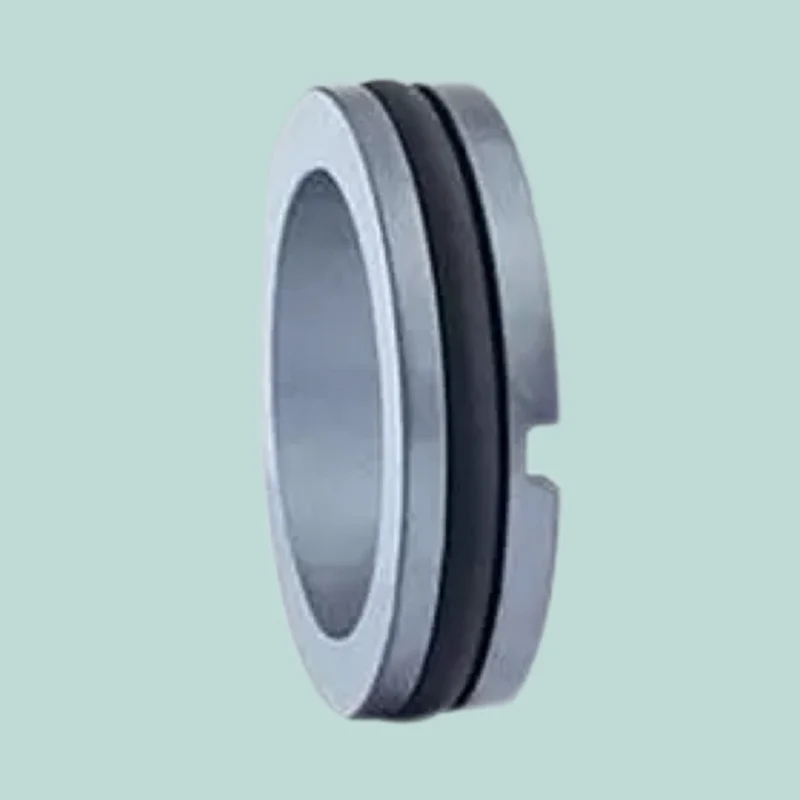

G50 Rubber Cup Mounted Standard Seat Stationary Rings For Water Pump

You can rest assured to buy G50 Rubber Cup Mounted Standard Seat Stationary Rings For Water Pump from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.