OEM Mechanical Seals

Precision Engineered OEM Mechanical Seals for Demanding Applications

As an industry leader for over two decades, we specialize in the design, engineering, and manufacturing of high-performance OEM Mechanical Seals. Our seals are not mere replacements; they are precision components built to integrate seamlessly into your original equipment, ensuring optimal performance, extended machinery life, and significant reductions in total cost of ownership. We partner with OEMs across sectors—from chemical processing and pharmaceuticals to water treatment, pulp & paper, and marine industries—to deliver密封 solutions that meet exact specifications and withstand the most challenging operating environments.

Our commitment to excellence is rooted in advanced material science, state-of-the-art manufacturing, and rigorous testing protocols. Every OEM mechanical seal is a product of collaborative engineering, designed to solve specific sealing challenges related to pressure, temperature, speed, and fluid compatibility.

Core Product Specifications & Technical Parameters

Understanding the detailed specifications of our OEM mechanical seals is crucial for proper selection and integration. Below are the key parameters that define our product range.

| Process Fluid Category | Recommended Primary Face Material | Recommended Secondary Seal (Elastomer) | Notes |

|---|---|---|---|

| Abrasive Slurries (e.g., Fly Ash, Mining Slurry) | Silicon Carbide (SiC) vs. Silicon Carbide | PTFE Wedges or Bellows | Hard face combination resists abrasion; PTFE eliminates elastomer degradation. |

| Hot Oils & Hydrocarbons (>150°C) | Tungsten Carbide vs. Carbon | FFKM (Kalrez®, Chemraz®) or Flexible Graphite | High-temperature elastomers or graphitic packing ensure thermal stability. |

| Strong Acids (e.g., Sulfuric, Hydrochloric) | Reaction-Bonded SiC vs. PTFE-impregnated Carbon | PTFE Bellows or FFKM | Superior chemical resistance; PTFE bellows offer excellent flexing and corrosion resistance. |

| Caustic Solutions (e.g., NaOH, KOH) | Nickel-Bound Tungsten Carbide vs. Carbon | EPDM or FKM | Avoid materials with silica (like ceramic) in high-pH environments. |

| Pharmaceutical / Sanitary (CIP/SIP) | Polished Silicon Carbide vs. Silicon Carbide | EPDM or FKM (FDA-approved grades) | Polished surfaces prevent bacterial adhesion; materials comply with FDA 21 CFR. |

| Light Hydrocarbons (Volatile, Low Lubricity) | Gas-Lubricated Dry Gas Seal Faces | O-Rings (FKM) for atmospheric side | Dry gas seal technology prevents vaporization at the face, ensuring zero emissions. |

Advanced Features of Our OEM Seal Designs

Our engineering focus extends beyond basic specifications to incorporate features that enhance reliability and ease of use.

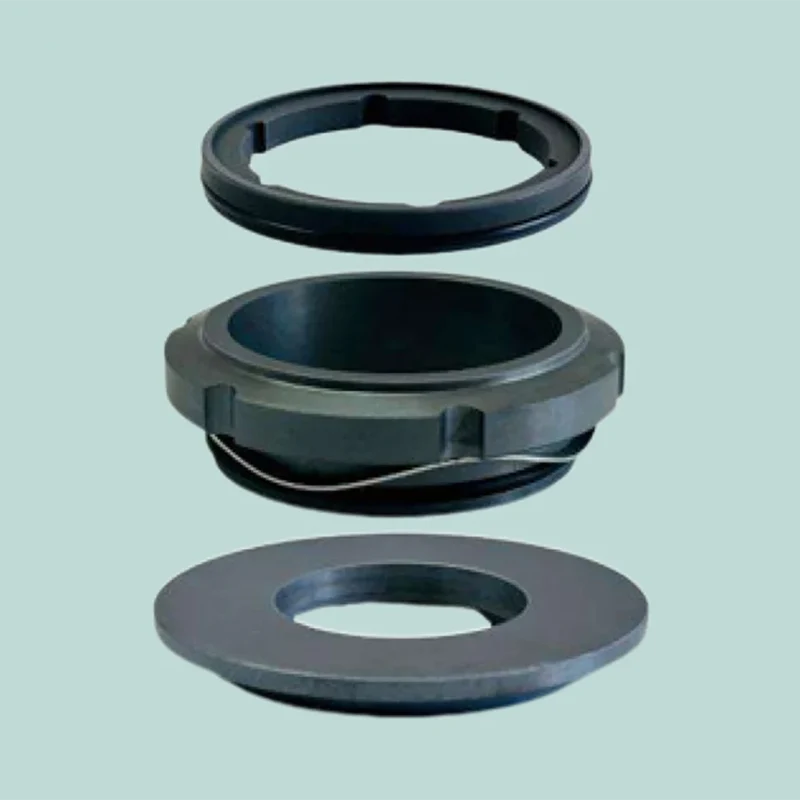

- Unitized Cartridge Design: Pre-assembled, preset, and ready to install. This eliminates measurement errors during installation, drastically reduces maintenance time, and guarantees optimal spring compression and alignment right out of the box.

- Advanced Face Geometry: Laser-machined hydro-dynamic grooves, spiral grooves, or T-grooves on the seal faces to generate fluid film lubrication, reducing heat generation and wear in challenging low-lubricity or dry-running conditions.

- Robust Drive Mechanisms: Positive drive mechanisms such as engineered drive bands, pins, or keyways ensure the rotary face follows shaft rotation without lag, preventing fretting and hang-up.

- Built-In Monitoring Ports: Standard provision for connections to pressure sensors, leak-off ports, or barrier/buffer fluid systems, facilitating integration with plant condition monitoring and control systems.

- Corrosion-Resistant Metallurgy: Housings, sleeves, and hardware available in 316 stainless steel, Hastelloy C®, duplex steels, and other alloys to match the corrosion requirements of the pump or vessel.

Frequently Asked Questions (FAQ) About OEM Mechanical Seals

Q: What is the typical lead time for a custom-designed OEM mechanical seal?

A: Lead time depends on the complexity of the design and material procurement. For standard designs with existing tooling, lead times can be as short as 2-4 weeks. For a fully custom seal involving new engineering, prototype testing, and sourcing of exotic materials, the process typically takes 8-12 weeks. We prioritize projects and offer expedited services for critical breakdown situations to minimize downtime for our partners.

Q: Do you offer seal support systems, and are they necessary?

A: Yes, we provide fully engineered support systems—including pressure control panels, reservoirs, coolers, and instrumentation—which are often critical for the reliable operation of double seals and dry gas seals. For a double seal, the support system maintains the correct pressure, temperature, and cleanliness of the barrier/buffer fluid. For a dry gas seal, it provides clean, dry gas at the required pressure. Using a properly designed support system is not just recommended; it is essential for achieving the published MTBPM (Mean Time Between Planned Maintenance) of the seal.

Q: How can we ensure the longest possible service life from our OEM mechanical seals?

A: Maximizing seal life starts with correct selection but depends heavily on installation and operation. Key steps include: 1) Ensuring the equipment (shaft runout, squareness, stiffness) is within OEM tolerances before installation. 2) Following our precise installation instructions for the cartridge seal—avoiding hammering, ensuring clean fluid flushes. 3) Gradually bringing the equipment up to operating temperature and pressure to avoid thermal shock. 4) Monitoring the support system (pressure, temperature, fluid level) as per our guidelines. 5) Implementing a basic condition monitoring routine for vibration and temperature at the seal chamber.

- View as

KPA/MSG Centrifugal Pump Water Seal Seal Model/Food Centrifugal Pump Mechanical Seal

You can rest assured to buy KPA/MSG 25mm Mechanical Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

Type 88 WAUKESHA pump UII Mechanical Seal Double Seals

You can rest assured to buy Type 88 WAUKESHA pump UII Mechanical Seal Double Seals from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

Type 87 WAUKESHA pump UI Mechanical Seal Double Seals

You can rest assured to buy Type 87 WAUKESHA pump UI Mechanical Seal Double Seals from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

Type 87 WAUKESHA pump UI Mechanical Seal

You can rest assured to buy Type 87 WAUKESHA pump UI Mechanical Seal from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

Burgman H12n Mechanical Seal Conical Spring Shaft Seal For Allweiler Hot Oil Pump

You can rest assured to buy Burgmann H12n Mechanical Seal Conical Spring Shaft Seal For Allweiler Hot Oil Pump from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.

SPF Mechanical Seal pump seal For Allweiler Pump SPF10, SPF20 replace Vulcan Type 8W

You can rest assured to buy SPF Mechanical Seal pump seal For Allweiler Pump SPF10, SPF20 replace Vulcan Type 8W from our factory.

Looking for a reliable China Mechanical seal manufacturer and supplier? Look no further! NINGBO BEST SEALS CO., LTD. is a leading factory offering high-quality OME mechanical seal.